Syncrosnap® Centrifugal Switches

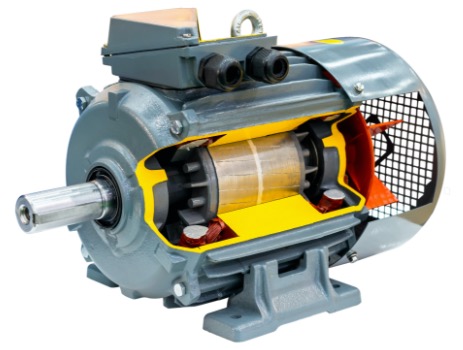

Our core competency is the design and manufacture of centrifugal mechanisms which control the start-winding of single-phase electric motors.

View Syncrosnap® Products

Motor & Switch Replacement Parts

Replacement switches are shipped from stock for quick turn-around for your motor repairs.

View Motor & Switch Replacement Parts

Speedetex Speed Switches

Reliable electro-mechanical and electronic speed responsive switches for measuring speed that's essential for performance and protection.

View Speedetex ProductsAbout Us

70+ Years In Business

Made In America

We’ve become the leader in centrifugal switch design after our founder developed a unique switching mechanism for controlling the auxiliary start-winding of single-phase electric motors.

Our Resources

TORQ™ Syncrosnap® Centrifugals

Download Now

Rotary Phase Converters 1

Download Now

Speedetex Rotary Speed Switch Overview

Download Now